Optimal Active Flow Control of Aerodynamic Configurations

For the design of modern aircraft, it is desired to attain a landing or take-off speed that is as low as possible. For security and constructional reasons, usually landing or take-off speed is limited. On the other hand, the designers face the trend of increasing aircraft weights thus increasing lift coefficients, which mean higher landing speeds. In order to generate enormous amount of lift at the lowest landing speed, high-lift devices are usually used. These can be classified as slats, flaps or the combination of the two. These methods are often called as passive methods. Another possibility is to use active flow control methods in order to increase the lift generated by the airfoil. One of the most common realisations of active flow control is the blowing and suction type. It has been demonstrated that this mechanism is very effective in delaying the flow separation. Most applications incorporate excitation at the leading edge in order to affect the boundary layer upstream of the point of separation, with periodic suction and blowing often proving superior to simple steady blowing and suction. One way of attaining this type of flow control is by varying the excitation parameters such as amplitude, frequency, position and direction of blowing/suction using trial and error methods. A single parameter can be varied manually in a series of numerical simulations in order to find its optimal value. However, with the increase in the number of control parameters, finding the optimal excitation parameters is computationally infeasible as it requires a very large number of flow simulations.

An efficient way of finding the optimal parameter set is by using the adjoint based methods, which belong to the family of gradient based optimisation algorithms. The adjoint methods can be classified into two, the continuous and the discrete adjoints. In the continuous adjoint method, one first derives the optimality system and the resulting adjoint partial differential equations (PDEs) are then discretised and solved numerically. Although computationally efficient, the continuous approach is known to suffer from consistency problems. In the discrete adjoint method, the discretised governing equations are used to derive the optimality conditions. Unlike the continuous approach, the discrete adjoints guarantee the consistency between the primal and discrete adjoint solutions on any arbitrary grid.

The development of adjoint approaches for unsteady optimisation problems is very challenging. One of the major difficulties associated with unsteady adjoints are the prohibitive memory requirements. This is due to the fact that one has to store the entire flow history during the forward-in-time integration of the primal equations, which is then used while solving the adjoint equations in reverse or backward-in-time integration. For example, the storage cost of 2D incompressible RANS flow solution on a relatively coarse grid with 100,000 grid points and 1000 unsteady time steps is of the order of O(10)Gb. Obviously, for many practical configurations in 3D with millions of grid points and thousands of time steps, the storage requirements can be prohibitively expensive. However, several strategies have been proposed to circumvent the excessive memory requirements. These methods are classified into two groups, namely the suboptimal control and exact methods. In exact methods, which we are interested in, flow solutions are stored only at distinct time steps, known as checkpoints. These checkpoints are then used as initial conditions to recompute the intermediate states that are not stored during the forward-in-time integration.

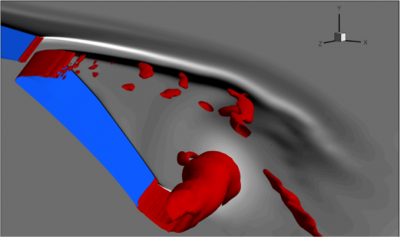

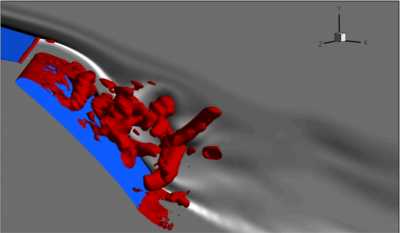

In this project, we aim at developing an unsteady discrete adjoint solver for unsteady optimal control of flows governed by incompressible RANS equations. The discrete adjoint code is developed in an automated fashion by using the Automatic differentiation. We want to apply the AD generated adjoint solver for optimal control of flows in high-lift configurations.

Partners: TU Berlin

Funded by DFG

Contact: Dr. Anil Nemili, Dr. Emre Özkaya and Prof Nicolas R. Gauger.